17) Which one of the following gauges is used for checking cylinders, which are not kept in vertical or horizontal position ?

Pilot gauge

Related Gauges MCQ - Machinist(Set-1) with Answers

Workshop gauge

One side

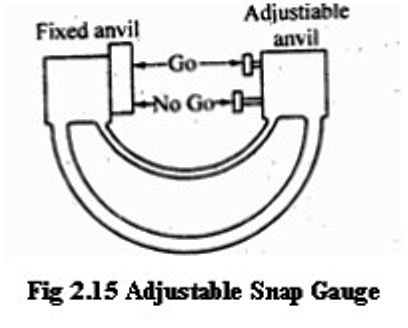

Adjustable snap gauges are used for checking large size shafts made with horseshoe shaped frame of I section. In an adjustable snap gauge, two adjustable jaws are provided on one side and one fixed anvil on the other side. The distance between the two anvils is adjusted by adjusting the adjustable anvils by means of setscrews. This adjustment can be made with the help of slip gauges for specified limits of size.

25.023 mm (Go) and 24.958 mm (No Go)

The "Go" and "No Go" sizes for a snap gauge like 25H7 indicate the acceptable dimensional limits for a specific feature on a workpiece. In the case of the 25H7 snap gauge, the numbers "25" and "H7" refer to a specific tolerance class and size.

In the ISO system for fits and tolerances, the number before the letter represents the basic size of the hole or shaft, and the letter indicates the tolerance class. In this case:

- "25" is the basic size.

- "H7" is the tolerance class for the hole.

25.002 mm (Go) and 24.977 mm (No Go)

The "Go" and "No Go" sizes for a snap gauge like 25H7 indicate the acceptable dimensional limits for a specific feature on a workpiece. In the case of the 25H7 snap gauge, the numbers "25" and "H7" refer to a specific tolerance class and size.

In the ISO system for fits and tolerances, the number before the letter represents the basic size of the hole or shaft, and the letter indicates the tolerance class. In this case:

- "25" is the basic size.

- "H7" is the tolerance class for the hole.