Dial test indicator

Dial Test Indicator Tools. Also known as a dial indicator or dial gauge, a dial test indicator (DTI) is a device used in various applications where small distances need to be measured accurately, such as checking run out on brake disks or end float on a crankshaft and concentricity of the outside diameter.

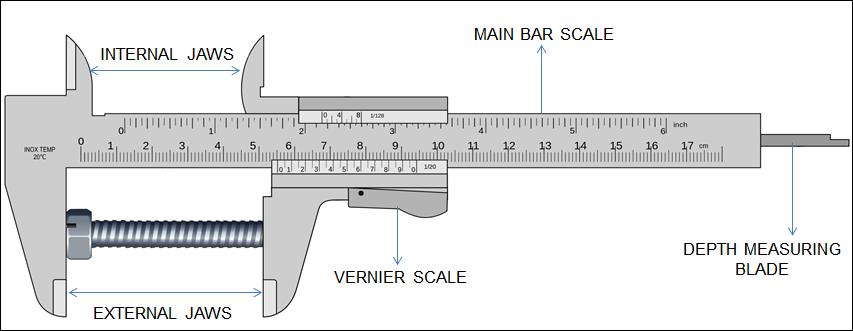

Least count

Least Count of an instrument is the smallest measurement that can be taken using an instrument. In other words, it is the smallest change an instrument can measure.

0.5 mm

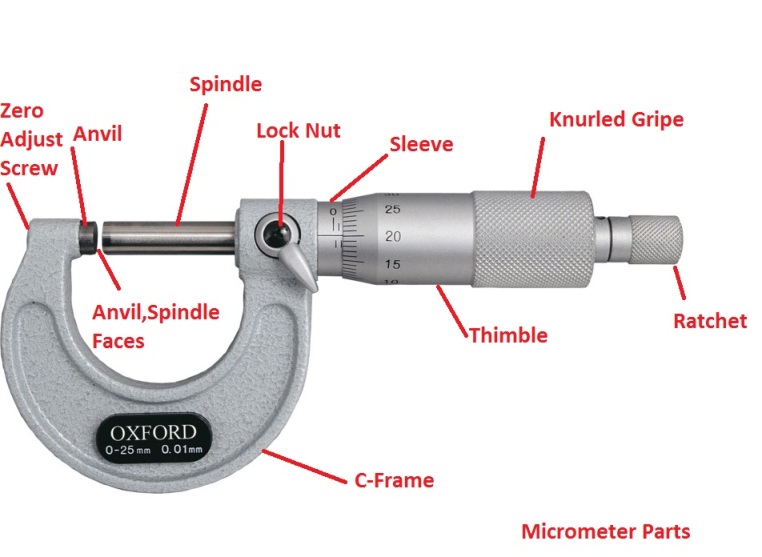

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimetre. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions.

Hence Metric outside micrometer has a threaded spindle with a pitch of 0.5 mm

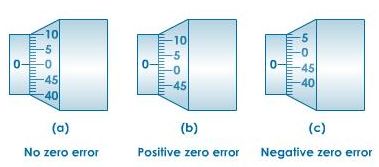

Zero on thimble and datum line on sleeve do not coincide when measuring faces are in contact

Zero error in micrometer occurs when zero on the thimble and datum line on sleeve do not coincide when measuring faces are in contact.

Lock the reading after setting it over the workpiece

The lock nut is simply a quarter turn nut that locks the spindle from turning. The sleeve contains the scale which is used to determine the measurement and the internal threads which allow the spindle to move.